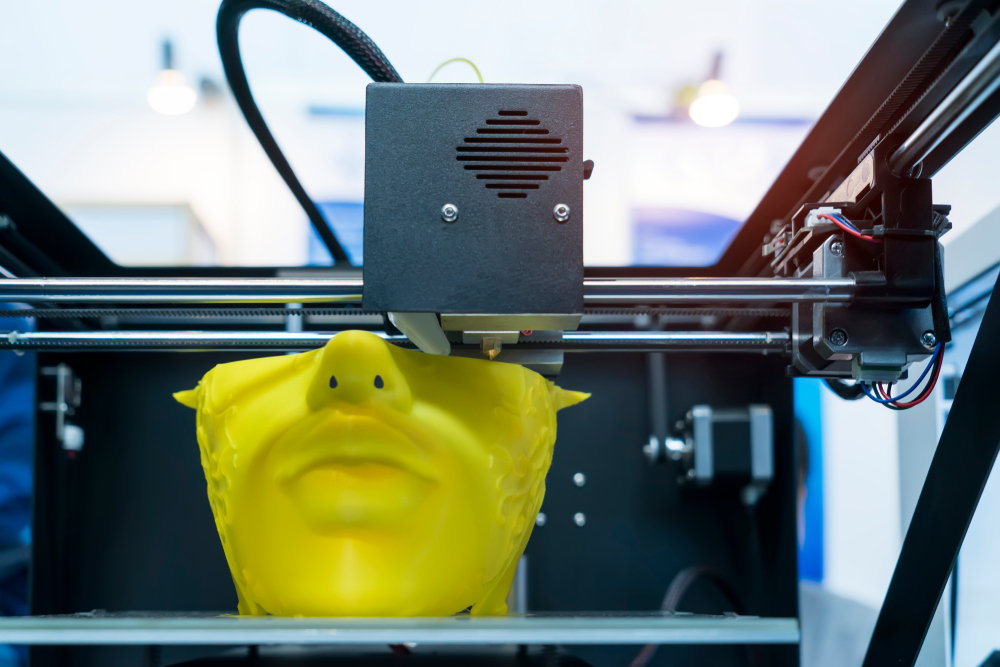

Today it is almost impossible not to have heard about 3D printing. Even though it’s so widespread, it is a pretty new printing method in the industrial sector which has been working with the same processes and methods for years. That is why industry hasn’t adopted this new technology as a regular tool. Very few companies have decided to take a risk and reap the benefits of 3D printing such as having pieces made using this method in their own machinery.

“Most of us engineers, have had subtractive training on the design of piece construction. This has changed suddenly and evolved into additive technology, which allows us to make shapes and things that we either couldn’t do before or just weren’t economically viable”, says Daniel Bosquet, Operations Manager of the Engineering LAB at BETWEEN.

To read the original version click on the image below