We help you in the evolution of your products for taking them to another level

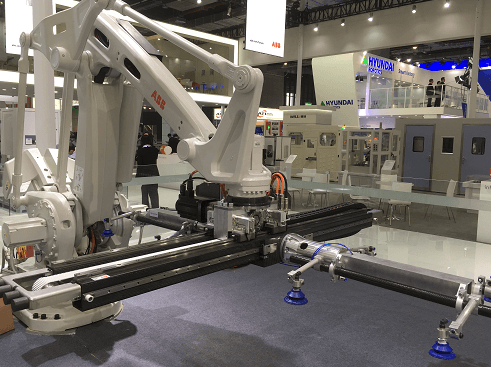

At BETWEEN we have a great back-office capacity that adapts to all our clients’ needs. From our technical offices we offer services according to every client’s needs, and the option of turnkey projects in Engineering, as well as in IT, taking on responsibility for all the development tasks related to the lifecycle of the product. We became technological partners of ABB when they requested to the Engineering LAB’s team the evolution of one of their most important products. Specifically, the robotization section of automotive sheet-stamping lines, shifting from its production in aluminium, to carbon fibre.

This project was born out of ABB’s needs to change their supplier, since the previous one was a German multinational with whom it was difficult to keep up with the project’s development. In addition, ABB saw that the processes were long and complex, so they looked for a supplier who would be able to provide a solution to these two needs.

Start of the project with BETWEEN Engineering LAB

During the first stages of the project, we detected that ABB wasn’t looking for a classic client-supplier relationship, but for a travel companion, that is to say, a company who collaborated with them hand in hand in the product’s development. And so, we did. Several tasks were taken care of jointly. For example, a comprehensive study of the product was carried out, providing design alternatives that could increase the product’s characteristics, as well as suggestions for the reduction of piece cost, and virtual assemblies for reducing the assembly integration time.

Our broad know-how allowed us to introduce value elements. This way, new concepts, which, thanks to our experience, we know that are vital for a serialised production, were incorporated too, among which are: FAT product validation, quality monitoring, mould tolerance, etc. Everything needed to offer an assembled product, validated and ready to be dispatched worldwide, made by just one integrator that allows to reduce or suppress additional internal costs.

We are currently putting the final touches on the last points of the LINAX unities supply contract for the coming years.

Article by Manel Juncosa, Technical Office Director.