BETWEEN Engineering Lab

From our technical engineering offices, we offer a variety of services tailored to each client’s needs, as well as turnkey solutions.

Project development & strategic consulting

Solutions adapted to your needs.

WHAT WE DO

At BETWEEN we can handle all the development tasks related to your product’s lifecycle.

FEM and CFD simulations.

Mechanical design. Product development.

Electronic design.

Special tools.

Test benches.

Prototypes and short-series production.

Offshore services.

Want more details on our back office engineering services?

Industry Sectors

Aeronautics.

Automotive.

Civil engineering.

Consumer products.

Distribution.

Electronics.

HVAC and refrigeration.

Catering.

Industrial equipment.

Mechanisms.

Medical.

Pharmaceutical.

Railroads.

Resources.

Transport.

References

ABB.

Alstom.

Ausa.

Bosch.

Comexi.

Faurecia.

Gehring.

Grifols.

Indra.

Lear Corporation.

Roca.

Ros Roca.

Telstar.

United Technologies.

Velcro.

Valeo Vistaprint.

HOW WE DO IT

In an environment focused on innovation and development, where major changes may take place throughout a project, with a high degree of uncertainty, and a finite timeframe and budget, success only comes through working as a competent, motivated and cohesive team.

The growth of our ENGINEERING LAB department is unarguably due to the professionalism of our team. This is why our management team’s primary goal is the growth of the team based on the following concepts:

Continuous training

Only a highly qualified team can successfully tackle the riskiest projects. Therefore, we cannot claim to be a leader in the industry without relying on a team who have received the best available training. To help achieve this, in the last few months our department has received training in foreign languages (English and German), operations management, electronic programming, pneumatic development, simulation (structural and fluids), team management, and other topics.

Work-life balance

At BETWEEN’s ENGINEERING LAB, we know that to keep a team motivated and proactive, it’s important to allow team members more freedom in terms of working hours than at standard companies. We offer a flexible work schedule to ensure our team is as focused and efficient as possible.

Career plans

To attract the best talent, we regularly follow-up on our team members’ career goals with the aim of reconciling their particular professional interests, the training made available to our team, and the company’s own goals.

Concurrent development

A specialized professional does not only need to have in-depth knowledge of his or her field, but also a clear understanding of the issues faced by his or hers colleagues in different disciplines. This is why our teams work on projects concurrently, with the primary actors assigned to the project regularly taking part in its development from the very start.

Team empowerment

One cannot effectively manage a team of experts (who are more experienced than their manager in their respective field), without listening to their advice and delegating responsibility. This is why decisions that impact the department are always openly posed to the team in order to reach a consensus that meets the needs of each member within the department.

Regular team building activities

The feeling of belonging to a team not only stems from technical and entrepreneurial factors such as those mentioned in the previous paragraphs (though these are also important), but it’s also critical to strengthen emotional ties. In our department, these efforts center around team building activities which are held on a regular basis.

At BETWEEN ENGINEERING LAB, the team comes first.

1. FEM and CFD simulations

Which new methods can provide effective FEM and CFD simulations in order to improve your design processes?

Computing power increases have popularized studies of FEM and CFD simulations. This has allowed the use of simulation to extend to various phases of product development:

Simulation during the initial stages of conceptual design.

Simulation to validate the design details.

Simulation during the functional validation test stages.

Sample CFD studies

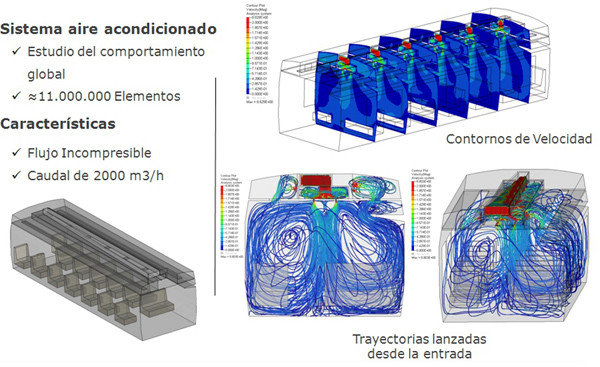

Air conditioning systems

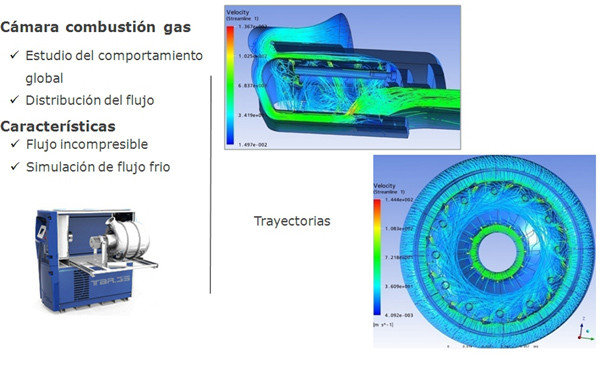

Gas combustion chambers

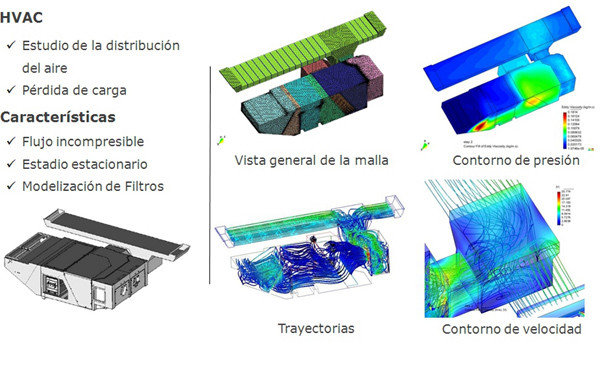

HVAC

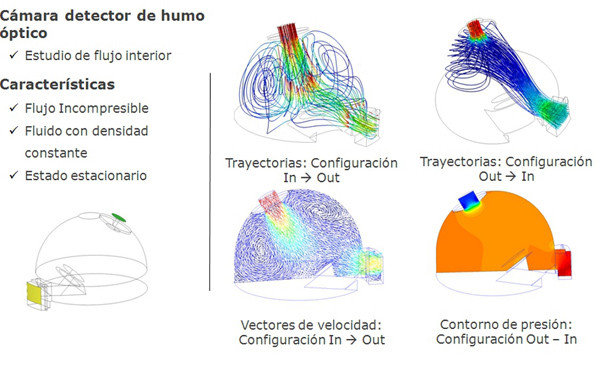

Optical smoke detection camera

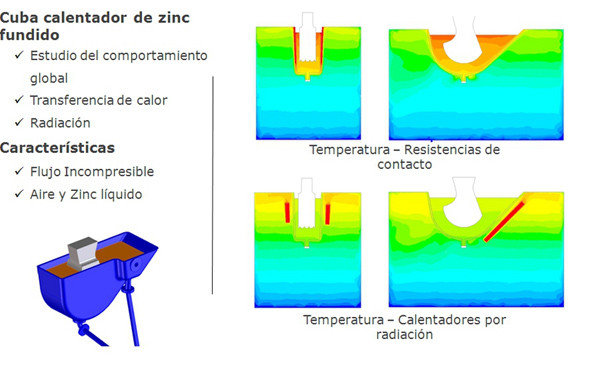

Molten zinc barrel heater

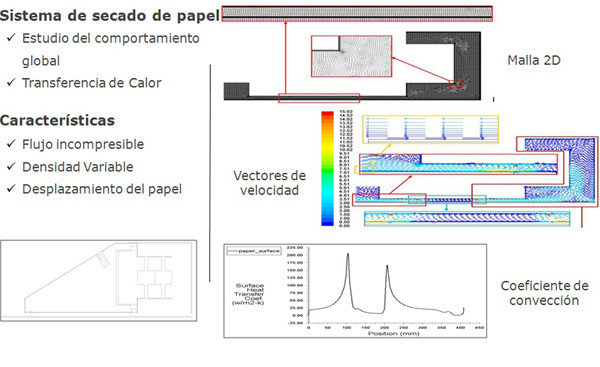

Paper drying system

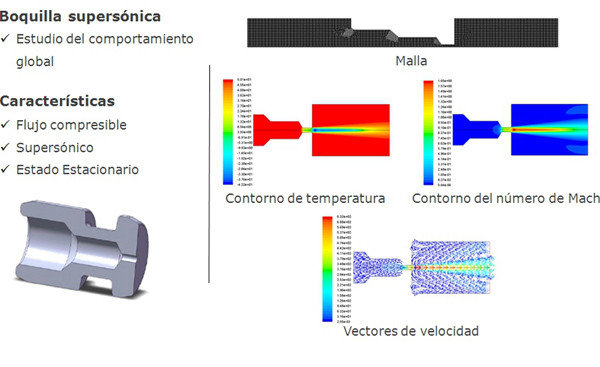

Supersonic nozzle

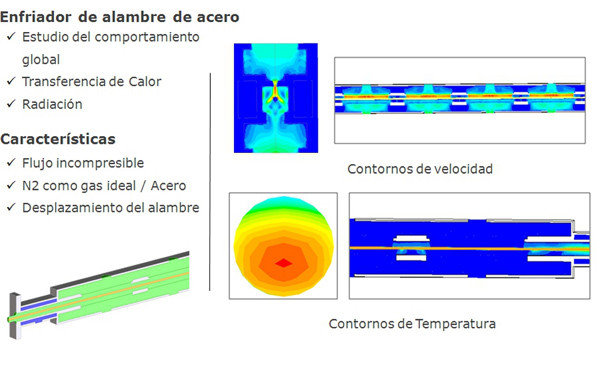

Cooler for continuous steel wire

FEM calculation examples

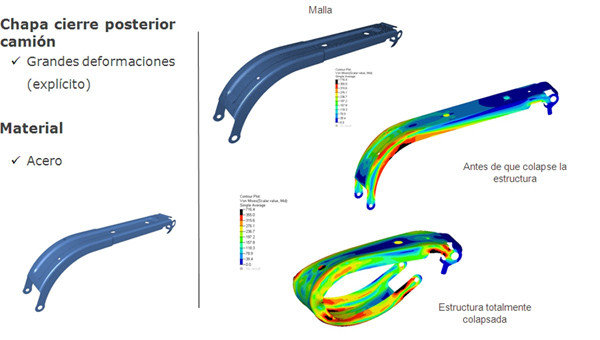

Truck rear closing mechanism

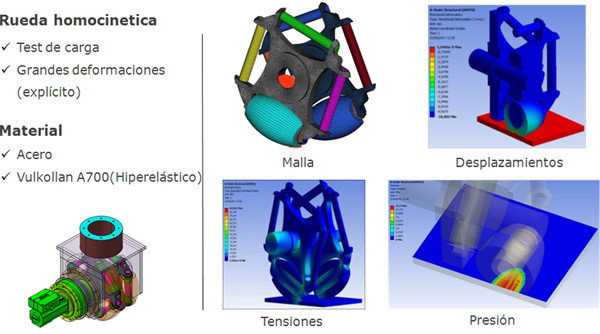

Velocity wheel

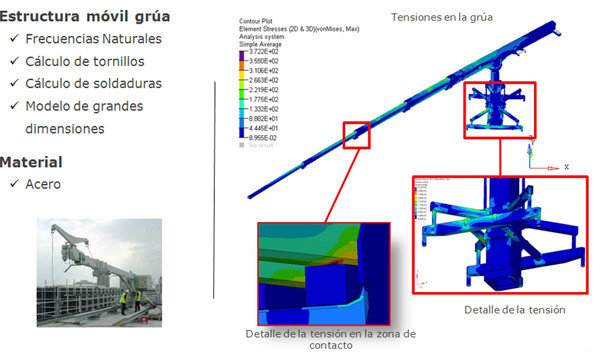

Mobile crane structure

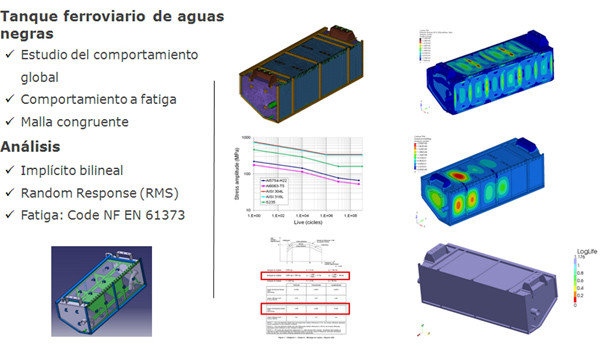

Under-carriage railway sewage disposal device

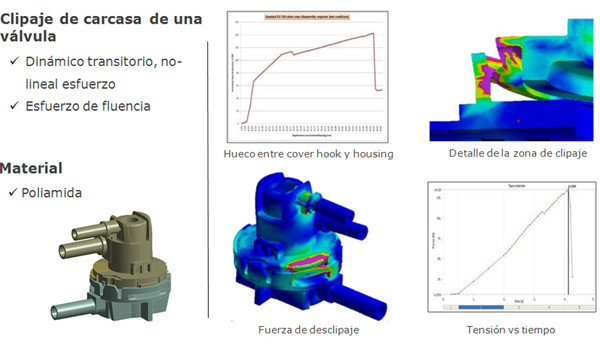

Valve housing clipping

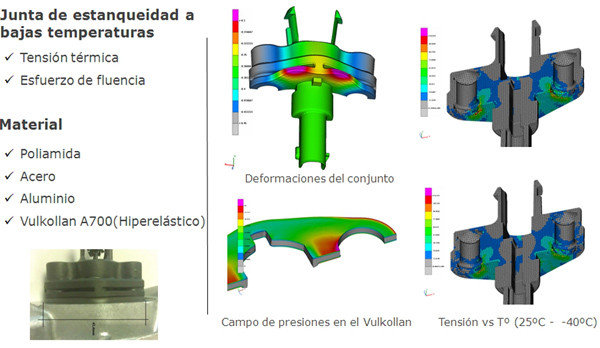

Low temperature watertight seal

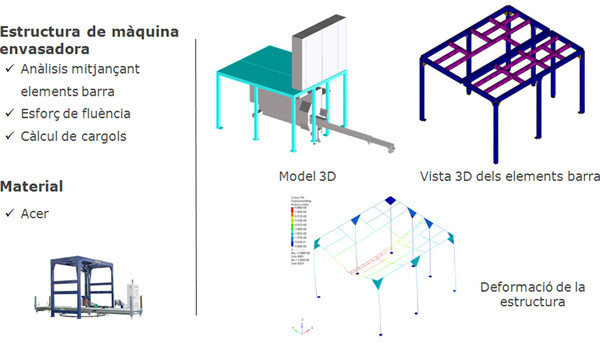

Packing machine structure

2. Mechanical design. Product development

What advantages does our technical support provide to our clients’ product development projects?

Cost reduction and flexibility of resources.

Efficient development, minimize deviations at the planning stage.

Expert technical capacity.

Mechanical design project examples

Industrial robot seventh axis

Design for high load gearbox

Transmission power steering bridge

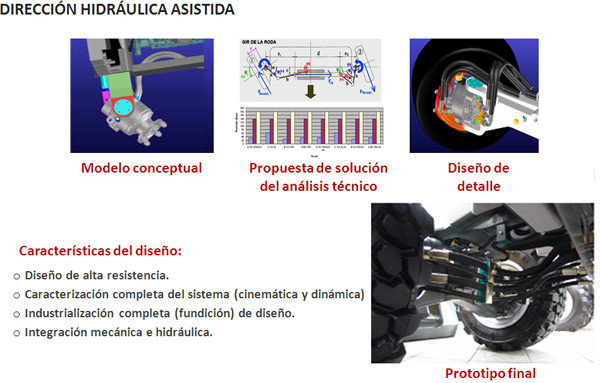

Hydraulic power steering

Antarctica mirror telescope positioner

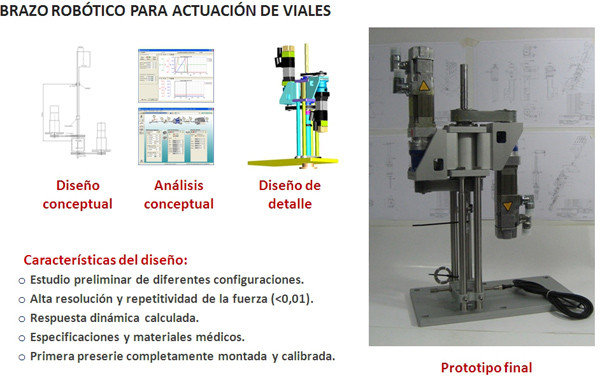

Robotic arm to activate tracts

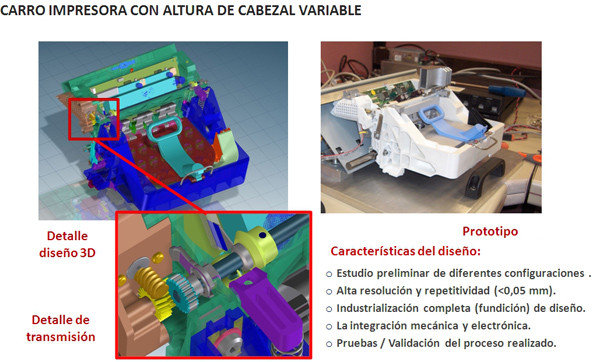

Carriage printer with variable head height

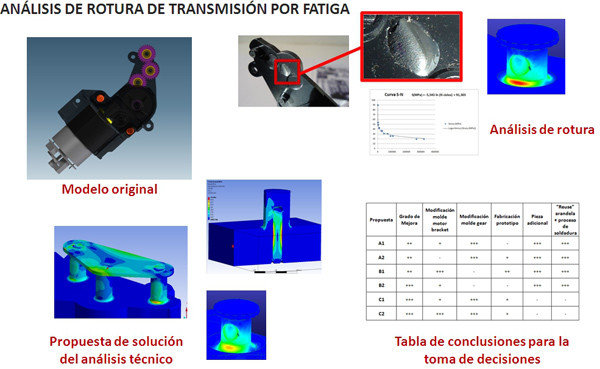

Analysis of drivetrain breakdown due to fatigue

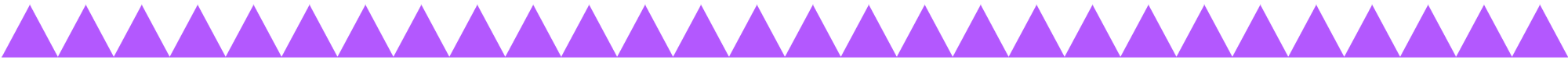

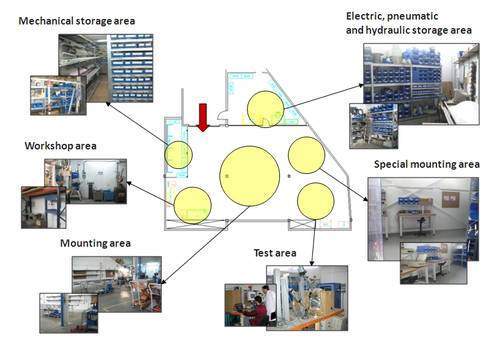

3. Electronic Design

At BETWEEN, we have significant experience with servo drive movement control technologies through our INGENIA Motion Control subsidiary. Learn more about our capabilities at www.ingeniamc.com.

We also have significant experience in:

Software development:

Embedded systems engineering.

Real-time systems engineering.

Many programming languages: C, C++, .NET, LabView, etc.

AUTOSAR expertise.

Hardware development:

PCB design.

PCB CAD library development.

PCB layout.

FPGA design services.

Complete design of the product including hardware and firmware development.

Pre-design and viability studies.

Handing of electronic design projects.

EMC pre-compliance.

Consulting and training.

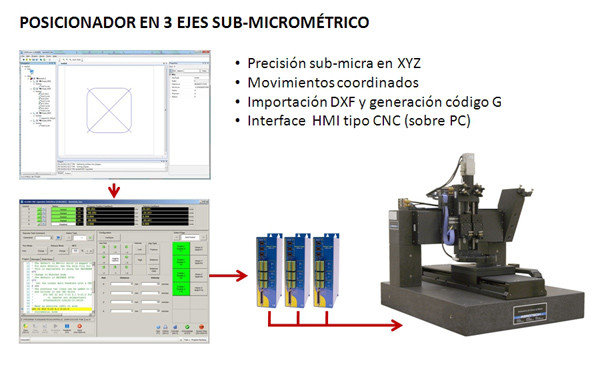

Sample electronic design projects

Optical positioning and tracking application

3-axis submicrometric positioner

High pressure servo drive

Servomotor development

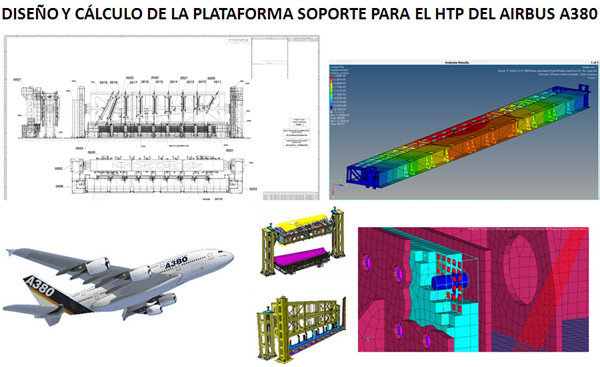

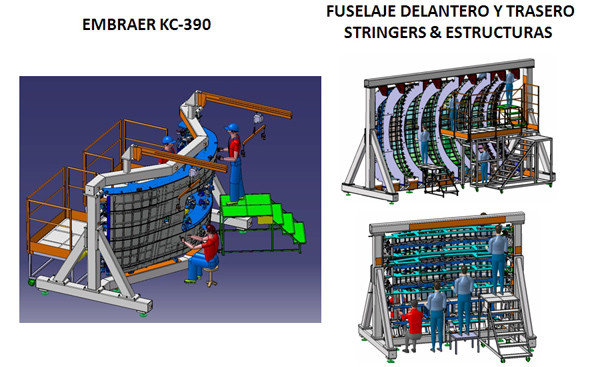

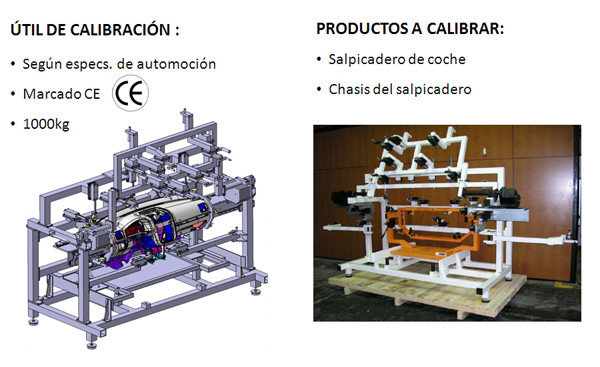

4. Special tooling

Need to optimize your manufacturing processes?

At BETWEEN, we specialize in creating custom turnkey solutions for projects requiring special tooling:

Assembly tools.

Precision machinery.

Technical documentation and CE marking.

Sample special tooling projects

Aerospace platform tooling

Aerospace fuselage tooling

Automotive calibration tooling

Tooling for electric cabinet assembly

Set of presses for assembly station

Vibration tooling for climate control equipment

Vibration tooling for windshield wipers

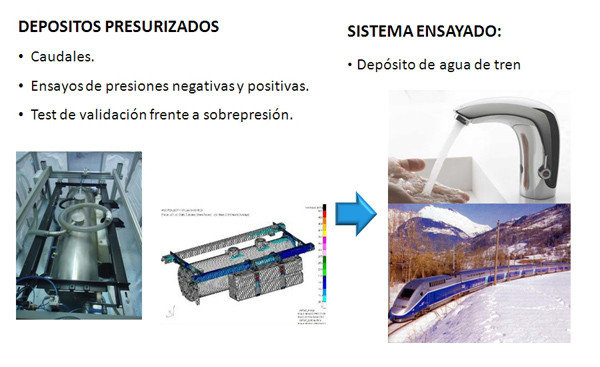

5. Test benches

Need to validate or test your product?

Solid experience in the design and construction of turnkey test equipment.

Considerable know-how in control and measurement of all types of physical parameters.

How do we do it?

Detailed study of each case.

Use the best materials and manufacturing techniques.

Final report and technical conclusions.

Sample test bench projects

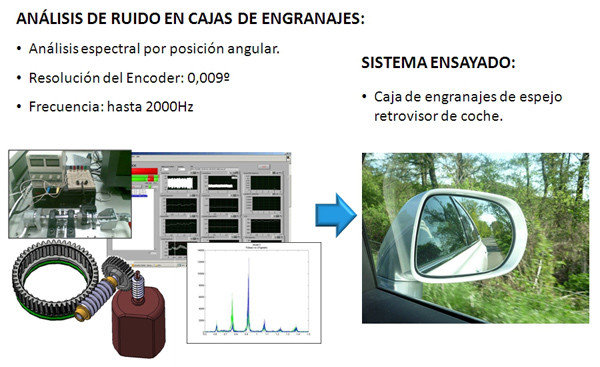

Analysis of rear-view mirror gear assembly noise

Testing railway car doors

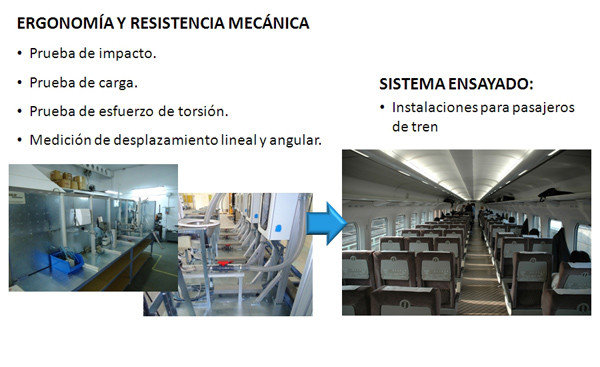

Testing rolling stock equipment

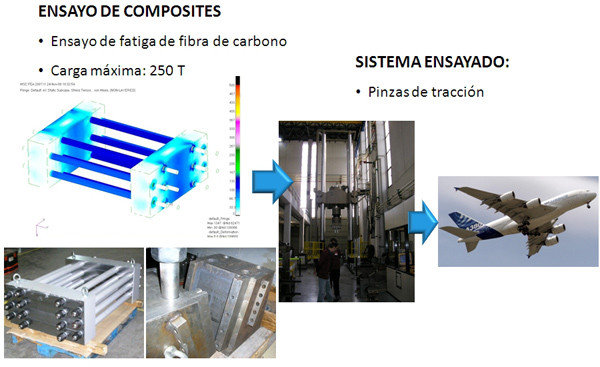

Fatigue test for composite material

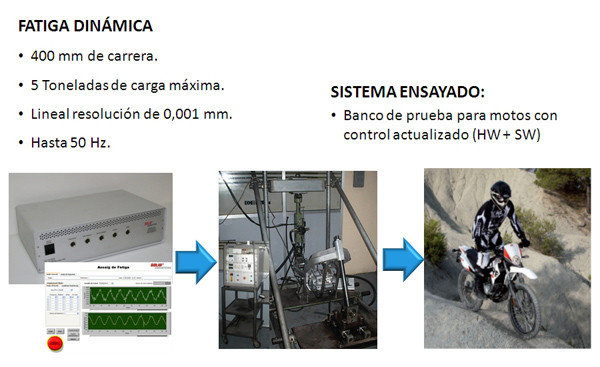

Dynamic fatigue tests

Switch lever reliability test

Brake lever reliability test

Switch lever noise test

Pressurized system test

Piping system test

Transition pulley dimensional analysis

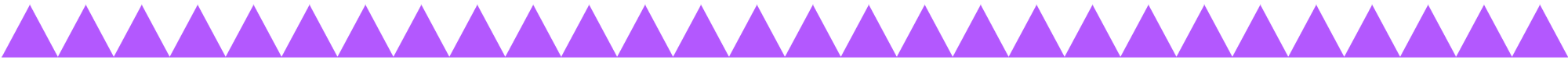

6. Prototypes and short-series productions

Manufacturing capacity.

Prototyping:

Industrial solutions for mechanization, processing and assembly of high precision elements.

Short-series production:

Mechanical devices containing mechanical, electrical, pneumatic and hydraulic technologies.

Manufacturing of products related to renewable energy.

Sample prototyping projects and short-series production

1 and 2-axis solar trackers

Specimen positioner arm

Servomotor development

7. Offshore services

BETWEEN offers offshore services to its clients through SOLID Engineering Sri Lanka (Pvt) Ltd.

Contact us and we will adapt to your needs, giving your projects the attention they need to allow you to meet your commitments in terms of volumes, delivery times, and/or costs.

We can create stable work teams which, based on your specifications and under our organizational and management umbrella, can achieve high efficiency at very competitive costs. .

Development of high work volume projects, including:

2D drawings based on 3D files in different formats.

Conversion of 2D drawings into 3D files.

Software migration, file conversion from one software application to another.

Creation of shielding for finite elements.